Here the truck is being charged while driving – soon this can become reality on Nordic roads

While there are more and more electric cars on Norwegian motorways, charging and range cause headaches for heavy transport. A solution may be power from above.

While there are more and more electric cars on Norwegian motorways, charging and range cause headaches for heavy transport. A solution may be power from above.

On the E16 north of Stockholm, Siemens and Scania are testing how to drastically reduce emissions from heavy transport by electrification. Photo: Siemens

“We lack the infrastructure and incentives needed to get emissions-free solutions for the transportation of goods. We are under time pressure to find an alternative to today’s polluting heavy transport,” says Torfinn Belbo, responsible for heavy transport at Zero, an independent environmental organisation.

Heavy road transport is expected to increase by 65 percent in the next few years, while Norway must cut emissions by 40 percent. This is a significant societal challenge, and the industry is calling for a helping hand to get started.

Christian Jahr is Head of Business Development at Siemens Norway. Photo: Berit Roald / NTB Scanpix

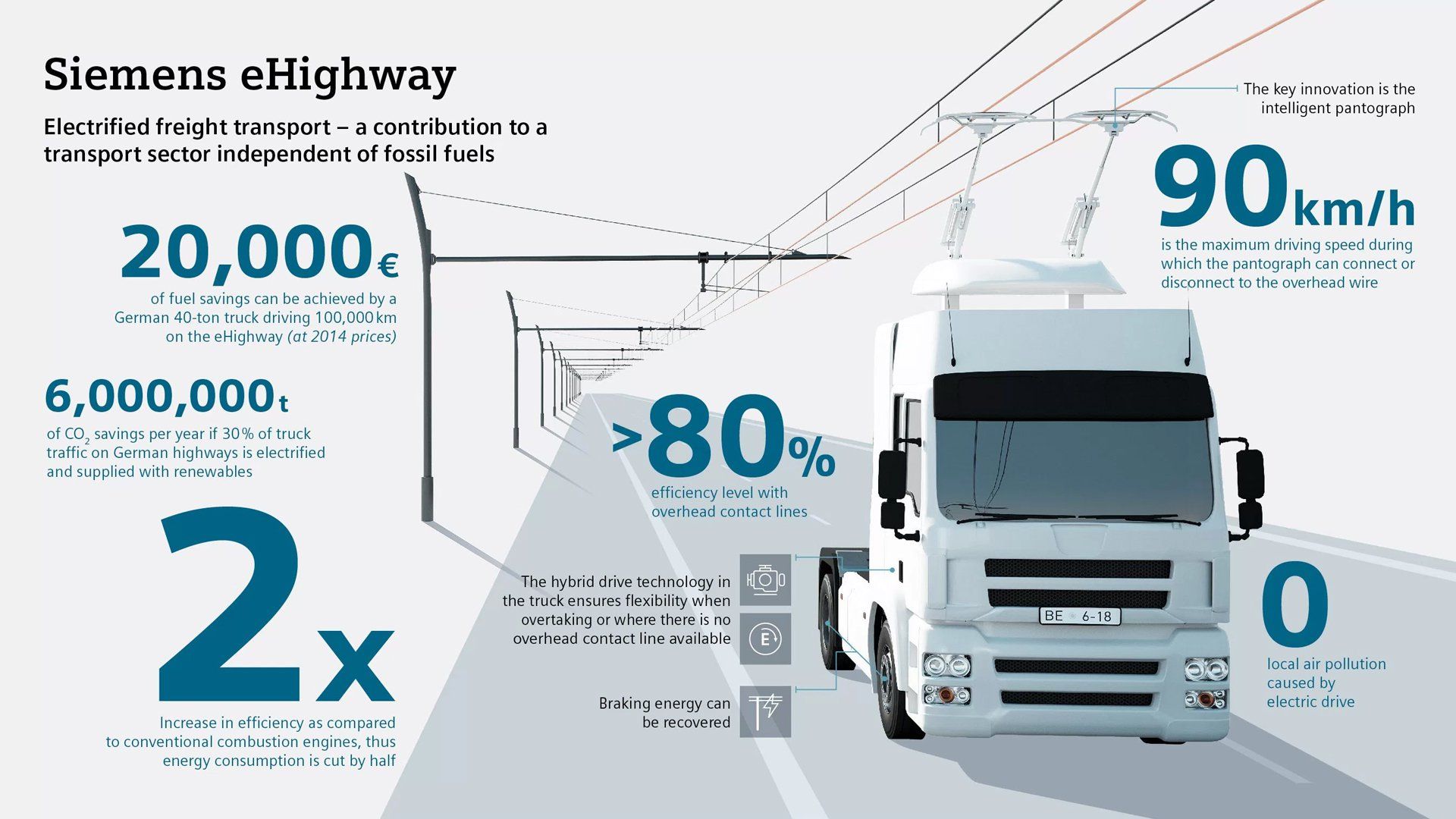

“eHighway is a well-proven and tested solution. It is based on known technology and can be rolled out on a large scale. There is also great commercial interest and that’s a sign that many believe in this development, which along with battery technology promises an exciting future,” says Belbo from Zero. He emphasises that other possible technologies must also be developed and tested to reach the emission targets.

The Norwegian National Transport Plan assumes that half of all new heavy vehicles will be emissions-free by 2030. The Norwegian Public Roads Administration has therefore launched the ‘Elingo’ project that looks at alternatives to electric heavy transport.

“We hope that this report will contribute to increased awareness and concrete measures from the Norwegian authorities, so the necessary conversion gets a boost,” says Jahr from Siemens.

For the best operating economy, a lorry should be on the road as much as possible. Solutions that allow cars to run electrically are both environmentally friendly and provide lower fuel costs. In addition, the solution saves time because lorries do not have to charge for many hours in a parking lot.

NOK 20 million per kilometre

Building an eHighway is a significant expense, but the advantage is that it can be established along already existing roads without having to make significant new investments.

“Our calculations show that the cost of an electric road with the eHighway concept costs about NOK 20 million per kilometre. This may sound expensive, but compared to what it costs to build roads in this country, it’s only a fraction,” says Jahr

Jahr emphasises that there is no question of building along all roads or along the entire stretch.

Concentrated on a few roads

“In Norway, we often get questions about how eHighway can be built on narrow roads, through tunnels and over bridges. That’s easy to answer. You don’t have to be connected all the time – it’s not like the old trolley buses hanging on their cables. The system can be fitted along the most suitable stretches, and elsewhere you drive on battery or internal combustion engine, completely seamlessly,” says Jahr.

Pantographs on lorries can be combined with all known lorry engines/motors and technologies.

“You can also charge any battery while the motor is running. This will make it possible to drive much further on clean, electric power,” says Jahr.

In Germany, they have estimated that 60 percent of all heavy transport accounts for two percent of the roads, equivalent to 4,000 kilometres. Along ten kilometres of these German roads, by the city of Hesse, an eHighway is now being built as a first step towards the zero-emission society.

Battery charging

Siemens is currently researching different technologies and solutions where battery technology is one of them. A battery that can be charged can easily be adapted to the normal use of a passenger car, but that is more challenging for heavy transport. One reason is because batteries are getting too heavy. For a 50-ton standard-mileage lorry used for long-distance haulage, the battery using today’s technology needs to weigh 20 tons.

“This is constantly evolving, but there are also not many natural layovers for lorries. They should preferably be on the road all the time. In addition, charging stations require large parking spaces,” says Jahr.