Now technology will make the world’s best drinking water even better

Aiming to ensure better water quality and fewer pipe bursts in the capital.

“Water loss from the distribution network is a major global problem. In developing countries, the loss can be up to 95 percent and in Europe up to 70 percent. In addition, we believe that the loss is often under-reported and that the values are low in relation to reality. This is not deliberate underreporting, but a result of a lack of overview,” says Aage Bjørn Andersen, General Manager of Sea-Lix.

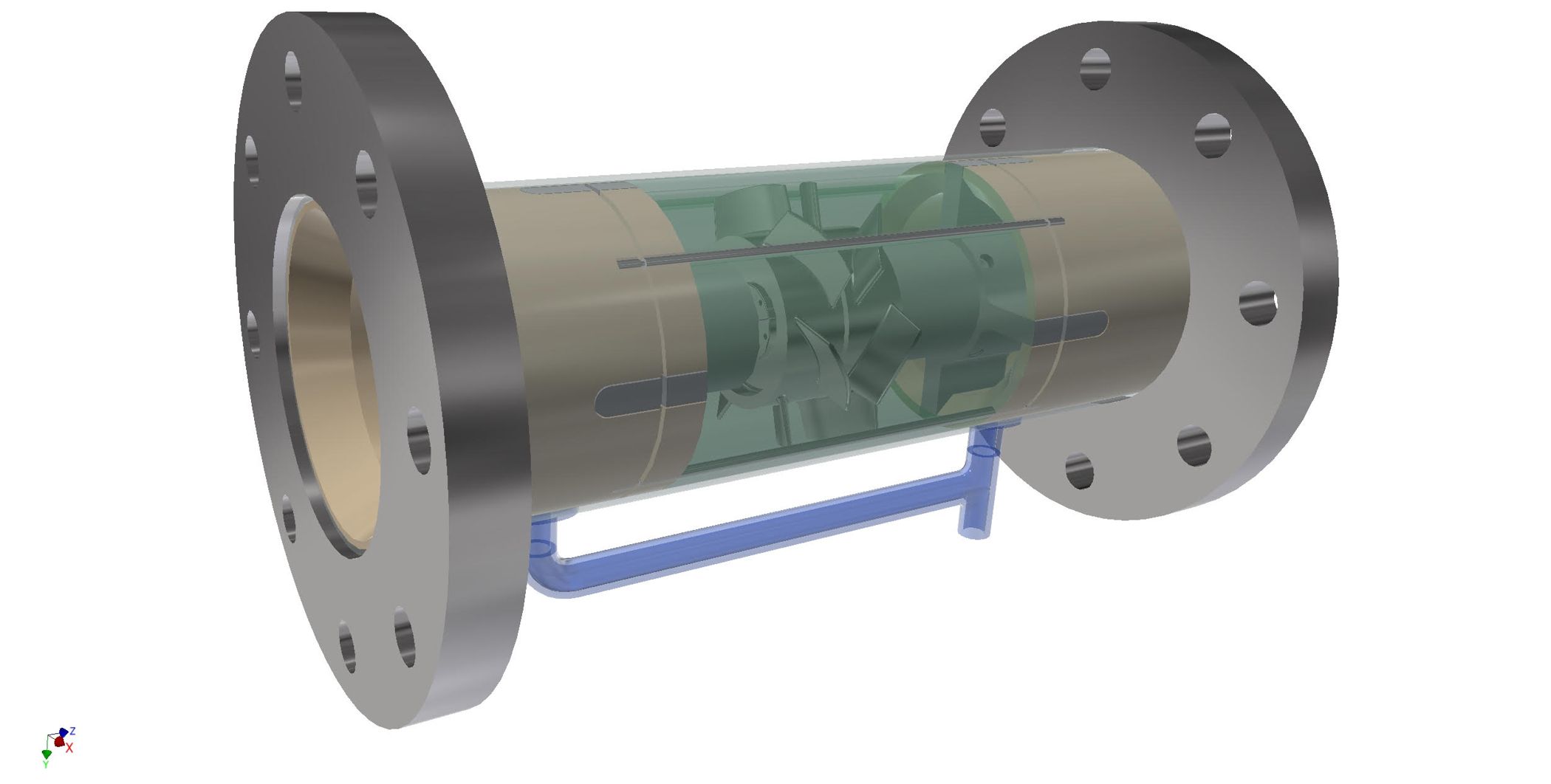

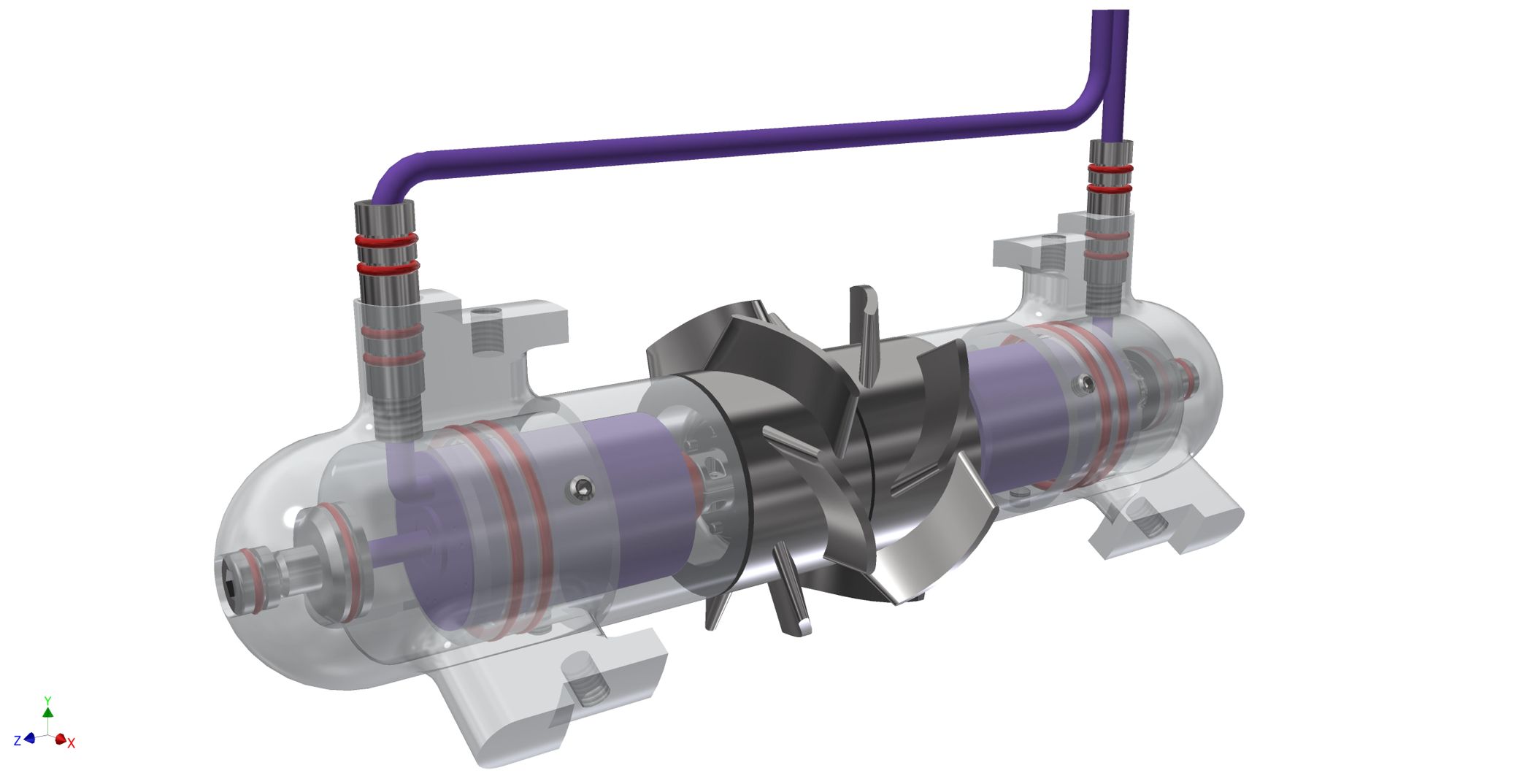

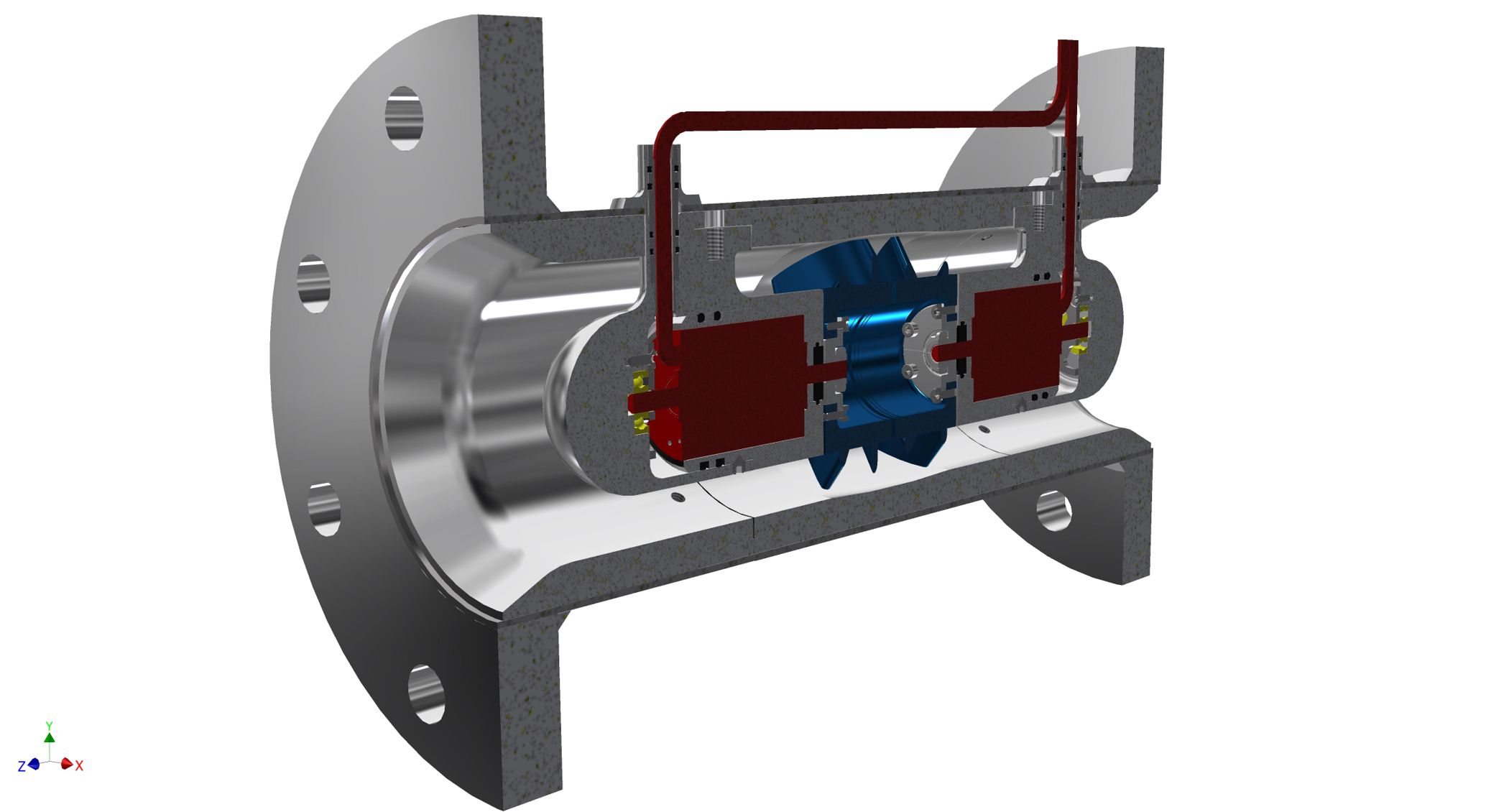

The company will monitor the real-time water distribution network using sensors mounted on turbines developed by themselves.

“One problem with water distribution is that you do not get enough data from the networks. Since there is no underground power supply, today’s solutions use batteries that send data once a day. With our turbines, we use some of the surplus pressure to generate power for our sensors, thus enabling them report continuously,” he says.

Andersen believes it is time for new solutions to gain full control of our drinking water.

“Existing solutions do not communicate with each other and data transfer from the sensors is incompatible. We want to find a solution to these challenges,” he says.

Aage Bjørn Andersen, CEO of Sea-Lix. Photo: DNX

Real-time data analysis

Sea-Lix cooperates with the Water and Sewerage Board to test the first turbine. The initial intention is to monitor pressure and quantity in water distribution systems, but in the long run it can contribute to more advanced monitoring.

“There are sensors that can collect qualitative data on contamination, bacteria, discoloration, conductivity, turbulence and other signatures from the water. Such surveillance over time generates large amounts of data that can be used for better maintenance, troubleshooting and the detection of leaks,” says Andersen.

The purpose of the project is to transfer data from the sensors via Siemens’ MindSphere so they can be used in the operation of the water distribution network.

“With this solution, operational engineers can monitor the status of water distribution in real time. We supply print data, forecasts and history. With this we create the basis for machine learning and the ability to predict consumption patterns,” he says.

Common platform

Among the company’s reasons for choosing MindSphere was the desire to enhance the quality of the interaction between the various sensor suppliers.

“MindSphere is an open solution that accepts many standards and can read data from both new and existing sensors,” says Security Specialist and Expert at MindSphere, Siemens, Knut Lønskog.

He explains how the operation centres at the waterworks can now integrate data from existing as well as new surveillance systems.

“The data collected provides a real-time status of the equipment being monitored. Together with maps and automated smartphone notification systems, the solution provides increased flexibility in operations,” he says.

Knut Lønskog is a security specialist and expert at MindSphere, Siemens. Photo: Siemens

«App Store» for industry and business

Industrial processes create huge amounts of data that have become a gold mine for computer analysts. With MindSphere, Siemens wants to visualise and analyse the data in a way that brings added value to different industries.

“Since MindSphere is an open operating system, users have the full freedom to develop their own solutions for specific industrial needs. If you are going to monitor a grain silo, a pump, a water purification plant or a fleet of electric boats or buses, this can now be done quickly and cost-effectively, says Lønskog.

Globally, Siemens has delivered over 30 million automation systems that can now be seamlessly connected directly to MindSphere.

“We have existing apps that provide insights into various industrial processes, but we also see many develop their own apps. The scope in an industrial context is great and we are approaching the point where we have an ‘app store’ for industrial IoT,” he says.

“The threshold to analyse industrial processes has been lowered, and we have only seen the beginning of digitisation,” Lønskog concludes.